Goal: When you have finished this laboratory exercise you will understand

- how to measure rheological properties of foods

and you will learn

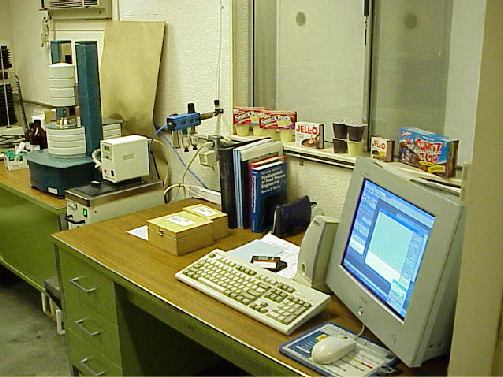

- the use of a rheometer to measure rheological properties

- the influence of temperature on rheological properties

-

Rheological properties are routinely measured in the food industry to design food processes, processing equipment, and quality control.

A number of different instruments are used, each with its own advantages and constraints. One of the common instruments used to measure rheological properties is a coaxial rheometer. This instrument is well suited for Newtonian and non-Newtonian liquids such as milk, fruit juices, ketchup, tomato paste, and fruit concentrates. -

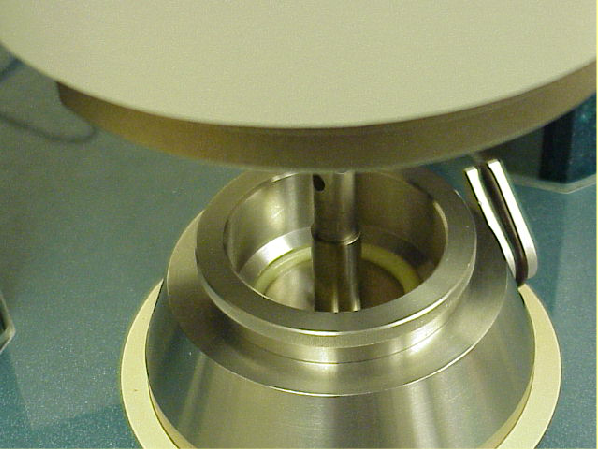

In a co-axial rheometer, a rotor revolves in a cylindrical cup. The liquid sample is in the annular space between the rotor and the cylindrical cup. The rheological properties of the liquid influence the torque required to rotate the rotor.

-

For a laboratory experiment, we use a rheometer and a sample of pudding. The following steps are used:

1) Using a syringe dispenser, extract a sample of pudding.

-

2) Empty the pudding sample in the cylindrical cup.

-

3) Lower the rotor in the sample.

-

4) Program rotor to rotate at desired speed.

-

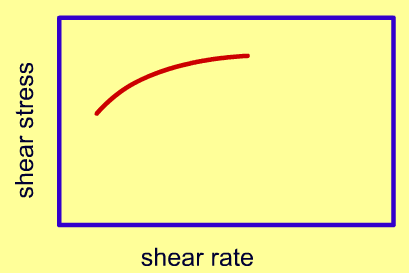

5) Record the shear stress generated at different shear rates.

-

6) Analyze the shear viscosity vs. shear rate data to calculate the rheological properties.

-

In a virtual experiment you will be able to select any temperature between 5oC and 35oC. The shear stress vs. shear rate will be plotted and saved in a spreadsheet.

-

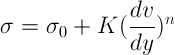

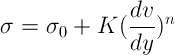

The flow characteristics of non-Newtonian fluids can be generally described by the Herschel-Bulkley model.

where k is the consistency coefficient, n is the flow behavior index, and σ0 is the yield stress.

A rheometer is used to gather shear stress vs. shear rate data. Using the Herschel-Bulkley model, rheological parameters (σ0, k and n) are calculated using data obtained with the rheometer.

-

1) Herschel-Bulkley model is a general equation useful to describe rheological properties of liquid foods.

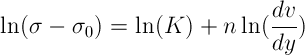

The Herschel-Bulkley model is rewritten as follows.

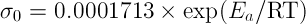

2) For given values of Ea, R and T, we can determine σ0 using the following equation obtained for vanilla pudding.

where T is in Kelvin

-

3) Using the equation for vanilla pudding, determine σ0 as shown in cell B4. Using calculated vallues of σ0, create columns of ln(σ - σ0) and ln(dv/dy) on the spreadsheet.

-

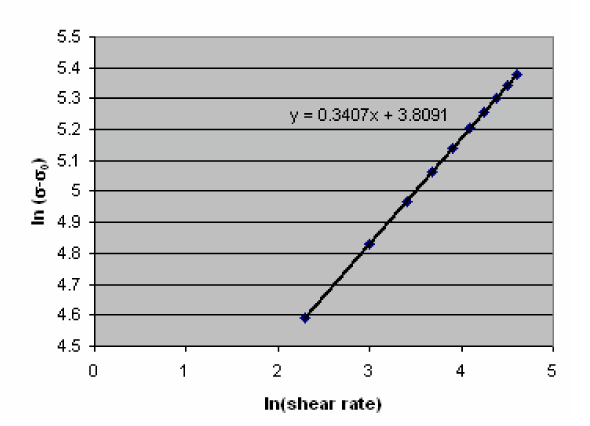

Plot ln(σ - σ0) vs. ln(dv/dy) and use Trend line to determine slope and intercept.

-

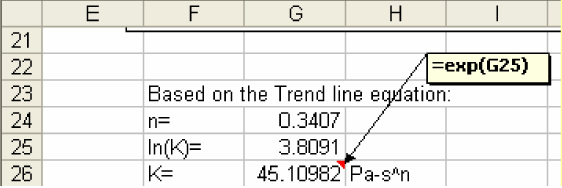

4) The slope gives the flow behavior index, n.

5) The consistency coefficient, K, is obtained from the intercept.

- Discuss how K and n values change with temperature for vanilla pudding.

- What is the influence of temperature on the K and n values

- Saravacos, G.D. and Kostaropoulos, A.E. (1996). Engineering properties in food properties simulation. Computers and Chemical Engineering. 20:S461-S466.

- Singh, R.P. and Heldman, D.R. (2009). "Introduction to Food Engineering," 4th ed., Academic Press, London.

- Steffe, J.f. (1996) "Rheological Methods in Food Process Engineering," 2nd ed., Freeman Press, E. Lansing.