Goal: When you have finished this laboratory exercise you will understand

- the mechanism of heat transfer in a heat exchanger

and you will learn

- how to determine the temperatures of fluid streams exiting a heat exchanger

- the difference between parallel and counter-flow heat exchanger

- the role of overall heat transfer coefficient in the design of a heat exchanger

-

Heat exchangers are widely used in food processing plants. A broad classification of a heat exchanger is based on whether any heating/cooling medium comes into contact with the product being heated or cooled.

In a non-contact type of heat exchanger, the two streams (heating/cooling medium and food product) are not allowed to mix with each other. This is generally accomplished by separating the streams with some type of a metal wall.

In a contact type heat exchanger, the heating/cooling and products streams are allowed to contact and mix with each other, e.g. in a steam injection heater. Some of the commonly used heat exchangers in food processing are shown in the following slides. -

Shell and Tube Heat Exchanger

-

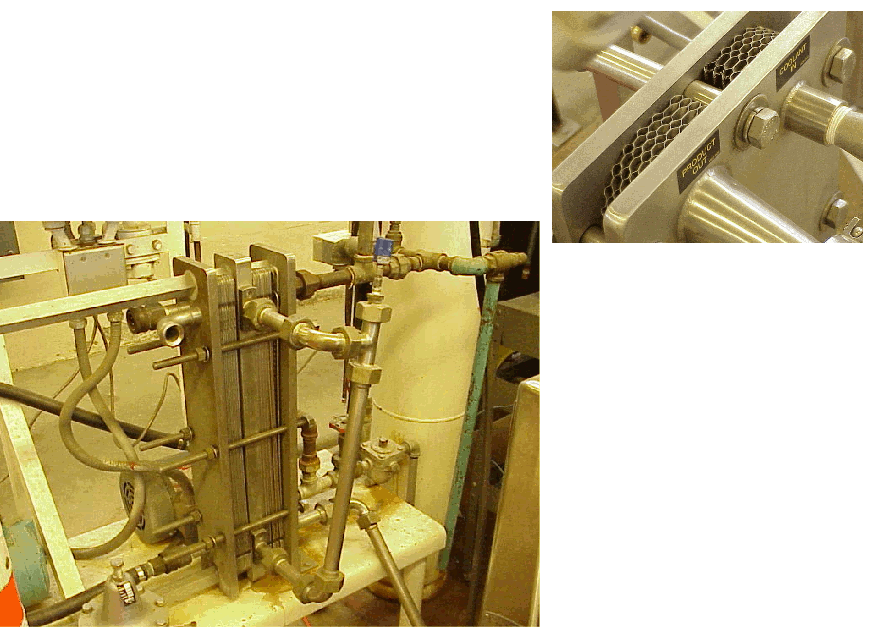

Plate heat exchanger are commonly used for heating and cooling milk, fruit juices, beer and wine.

-

Plate Heat Exchanger

-

A plate heat exchanger used in a dairy plant -

A plate heat exchanger used in a dairy plant

-

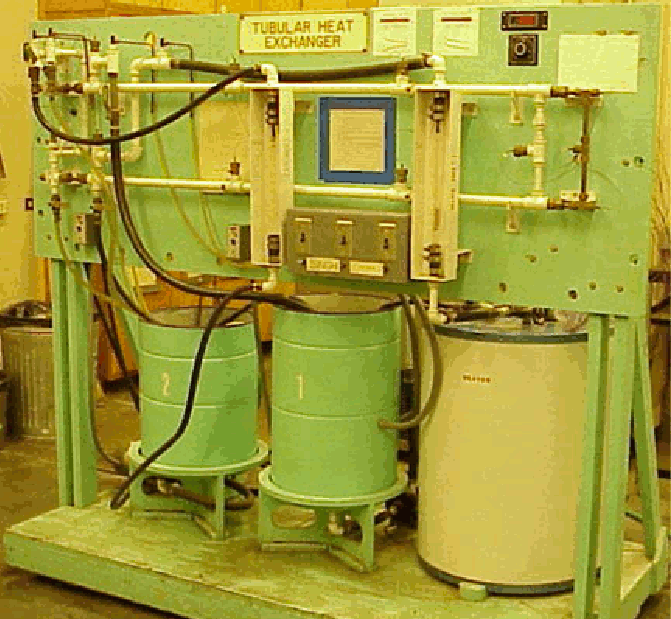

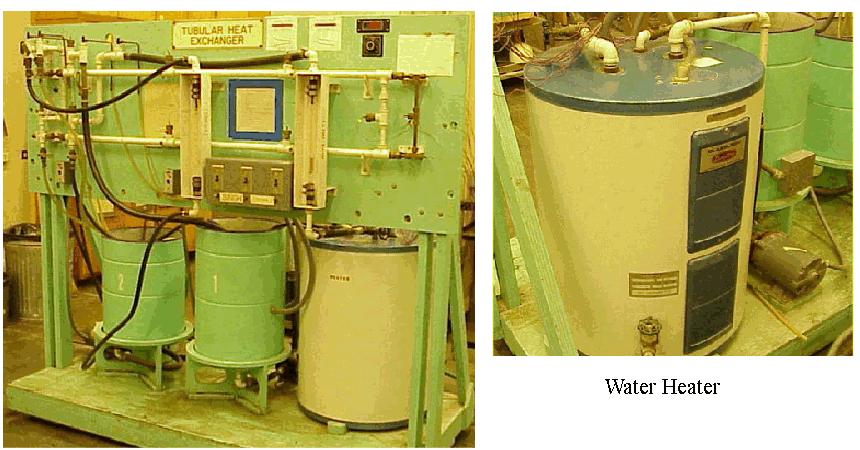

In a laboratory experiment, we will use a double pipe heat exchanger as shown below:

-

In this heat exchanger, we will heat water in a water heater (similar to the one commonly used in domestic water heating). Hot water is then pumped in the outer pipe of the heat exchanger. In the inner pipe, cold water is pumped to obtain heated water at the exit.

-

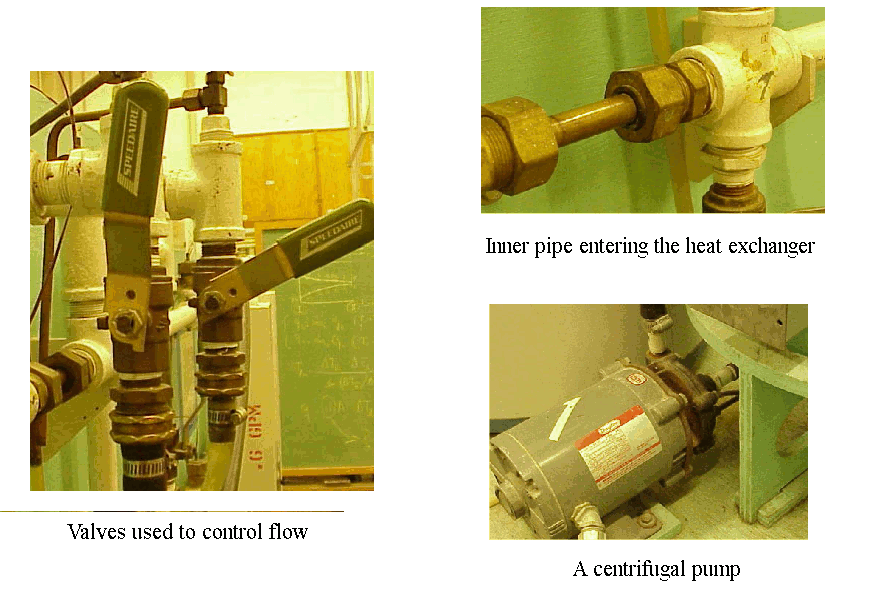

A centrifugal pump is used to pump cold water through the inner pipe. Valves are used to adjust flow rates.

-

Thermocouples are installed along the length of the pipe to obtain temperature distribution. Flow rate of the fluid streams is measured using flow meters.

-

We operate the heat exchanger with different flow rates and measure the inlet and exit temperatues of the two fluid systems.

The inlet and exit temperatures of both fluid streams are used in calculating log mean temperature difference. The rate of heat transfer is calculated knowning the log mean temperature difference and flow rates. -

For the virtual experiment, enter the inlet temperatures and mass flow rates of the product (milk) and heating fluid (hot water) streams, type of flow, inside pipe radius, and length of the heat exchanger. Determine the outlet temperatures of both fluid streams.

-

In designing heat exchangers, prediction of the exit temperature of the fluid streams is an important task. Assuming steady state heat transfer, two general methods are used for this purpose: log mean temperature difference (LMTD) and effectiveness-NTu (number of thermal units) method.

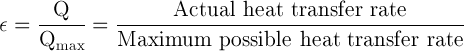

Log Mean Temperature Difference: The temperature difference between the two fluid streams varies along the length of the heat exchanger. This difference is expressed as a log mean temperature difference:

where ΔT1 and ΔT2 are the temperature differences between the two fluids at the inlet and outlet of the heat exchanger.

The effectiveness-NTU method is used to determine the outlet temperature of the two streams for known mass flow rates (kg/s) and inlet temperatures for a given heat exchanger. This method is based on heat transfer effectiveness, ε, given as

-

Using the results, calculate the following:

1. the logarithmic mean temperature difference

2. the overall heat transfer coefficient (U value)

3. the effectiveness values with the calculated outlet and inlet temperatures for each trial for counter and parallel flow conditions.Compare counter flow and parallel flow heat exchangers based on the logarithmic mean temperature difference, overall heat transfer coefficient, and effectiveness values.

- Based on the calculated values of the logarithmic mean temperature difference, overall heat transfer coefficient and effectiveness, which flow option would you choose for a double pipe heat exchanger? Why?

- Are there any situations when a parallel flow option may be preferred instead of a counter flow heat exchanger?

- Cengel, Y.A. (1988). "Heat Transfer: A practical Approach," McGraw-Hill, Inc., Highstown, N.J.

- Holman, J.P. (2001). "Heat Transfer," 9th ed, McGraw-Hill, Inc., New York.

- Singh, R.P. and Heldman, D.R. (2009). "Introduction to Food Engineering," 4th ed., Academic Press, London.