Goal: When you have finished this laboratory exercise you will understand

- how moisture diffuses in foods during drying

and you will learn to

- to determine the diffusion coefficient of water vapor in a potato sample during drying using a given analytical equation, and

- to determine the effect of drying air velocity on the moisture diffusion coefficient.

-

The removal of moisture from a food product is one of the oldest preservation methods.

By reducing the water content to lower levels, microbial proliferation and other deteriorative reactions are reduced significantly.

Design of industrial drying processes requires careful analysis of heat and mass transfer occurring within the product.

For mass transfer related calculations, knowledge of diffusion coefficient of water in the inside and mass transfer coefficient on the outside of the product are required parameters.

-

A slab-shaped potato will be used in this experiment. After determining the initial moisture content of the potato sample, its weight change will be recorded during drying.

Thickness and initial moisture content are kept constant at 10 mm and 80%, respectively.

A batch dryer is used in this experiment. This dryer has an electric heater, a blower, a plenum chamber and the drying zone. Typical controls fro this dryer include the control of the heated air temperature and air velocity. -

Heated air temperature of 60oC and the air velocity of 1, 3 and 5 m/s are selected for this experiment to determine the effect of air velocity on the diffusion coefficient.

The relative humidity of heated air is kept constant at 50%.

Total drying time for each trial is selected to be 240 min as default.

The weight change of the potato sample during drying will be obtained using a weighing scale located inside the oven.

-

Drying is a simultaneous heat and mass transfer process since it involves the application of heat and removal of water at the same time.

In modern drying processes, a heat source and a fan is used to move hot and dry air over a food material.

Heat and mass transfer are both increased by moving an air stream resulting in a reduction of drying time.

Mass transfer coefficient of the drying medium and the diffusion coefficient of the water inside the product play significant roles in drying time from a mass transfer point of view. -

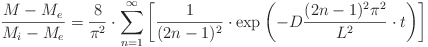

There are different analytical and numerical solutions of the governing equations used to determine the drying time for a given range of average moisture content or to determine the average moisture content of the food material for a given time. The following equation is suggested to determine the average moisture content change of an infinite slab shaped material:

Diffusion coefficient (D) of the moisture in foods under given processing conditions is an important parameter that influences the drying rate.

-

In this experiment, the weight change of the food material during drying will be recorded, and the calculated moisture content change will be used to determine the diffusion coefficient using this equation.

The data analysis will include mathematical approaches to determine the diffusion coefficient value using the given equation and experimentally obtained weight change data.

-

In this laboratory exercise, you obtained data on change in weight for a slab-shaped potato sample subjected to different air drying conditions. To determine the moisture diffusion coefficient using the experimental data:

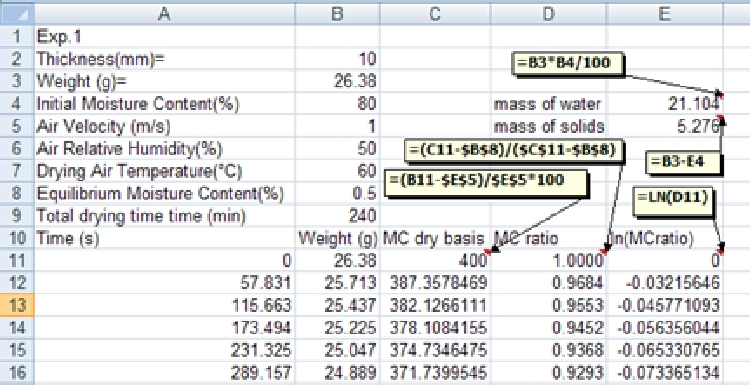

1. Calculate the change in moisture content from the weight loss data - after copying the experiment data on an Excel spreadsheet, calculate the total moisture and dry material in the sample.

2. Calculate the moisture content ratio in dry basis (see the following figure). -

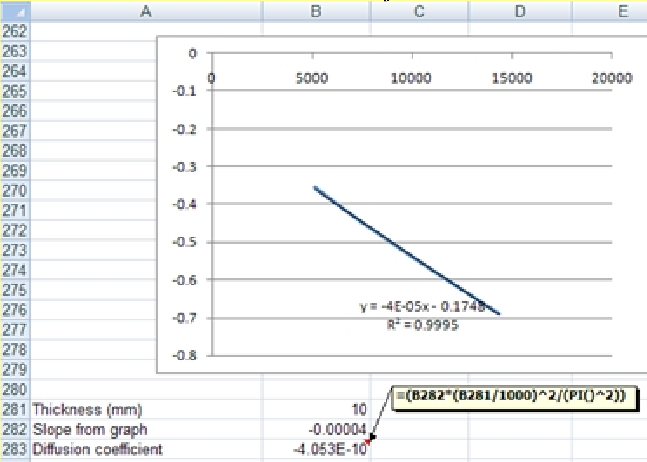

3. Draw the linear portion of moisture content change versus drying time and determine the slope using the TrendLine Procedure.

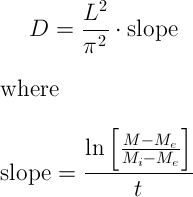

4. Using the slope, the diffusion coefficient may be calculated applying the following equation: -

- How did the diffusion coefficient change with the change of air velocity? Discuss the reasons.

- Would you expect a change in the diffusion coefficient with an increase in drying air temperature or drying air relative velocity? Discuss.

- What is the effect of product thickness on the diffusion coefficient?

- Barbosa-Canovas, G.V. Ma, L. and Barleta, B. Food Engineering Laboratory Manual. Technomic Publishing Company, Inc. Lancaster, PA.

- Fellows, P.J. (2000). Food Processing Technology: Principles and Practice. CRC Press, Boca Raton, FL.

- Heldman, D.R. and Hartel, R.W. (1997). Principles of Food Processing. Chapman & Hall, New York, N.Y.

- Singh, R.P. and Heldman, D.R. (2009). Introduction to Food Engineering. Academic Press. San Diego, CA.